In today's world, the ever-increasing amount of plastic waste poses a significant challenge to our environment. Various industries, from packaging and agriculture to manufacturing and logistics, contribute to this growing problem. Finding effective and sustainable solutions for managing this waste is crucial for a healthier planet.

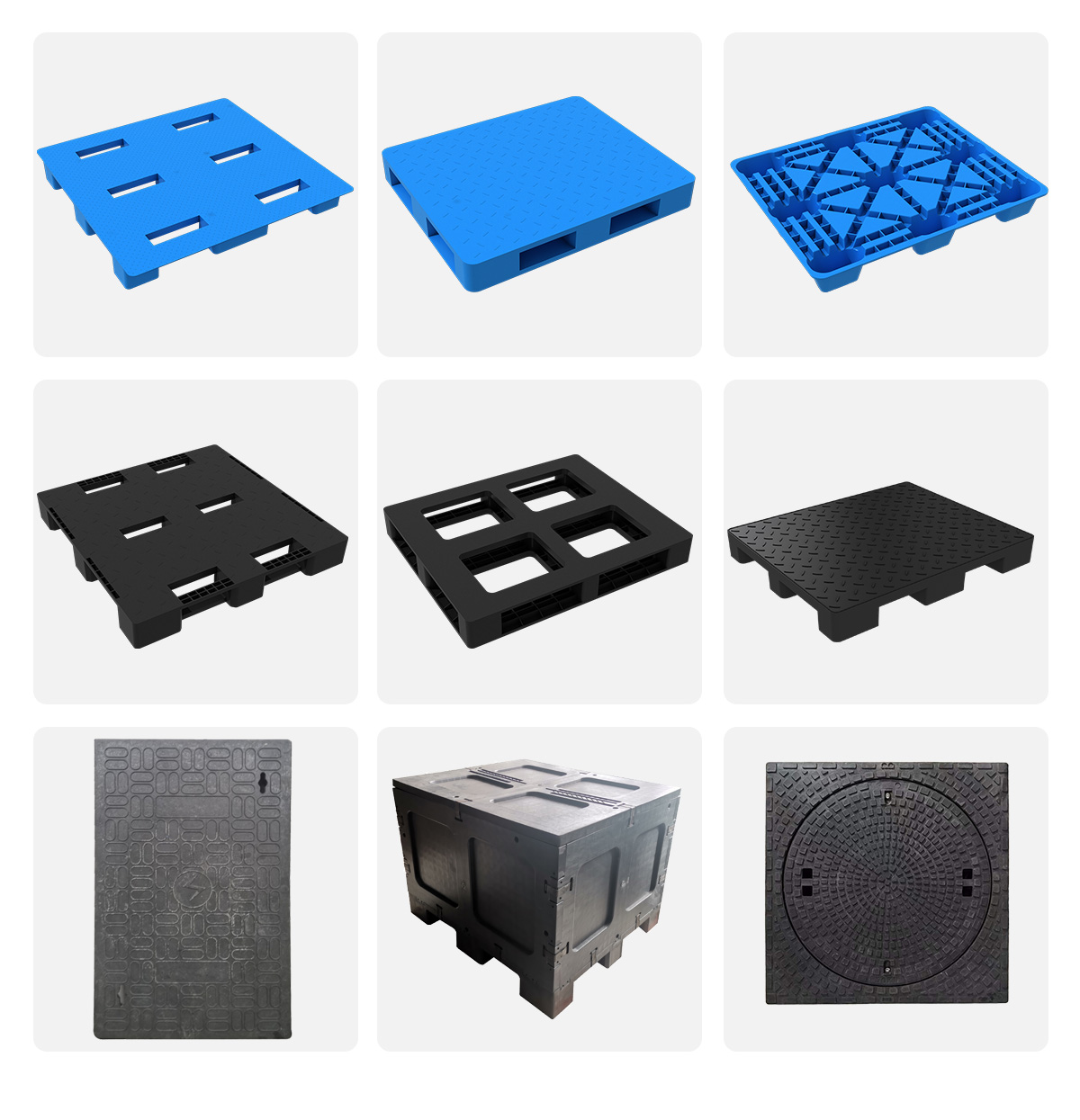

At PalletMach,we understand this challenge deeply. That's why we specialize in manufacturing compression molding pallet machines – powerful and innovative equipment designed to tackle the plastic waste issue head-on. Our machines offer a practical and environmentally sound method to recycle a diverse range of waste plastics, transforming them into durable and valuable assets: plastic pallets.

Our compression molding pallet machines are engineered to handle a wide array of plastic waste, offering a versatile solution for numerous industries. This includes, but is not limited to:

Post-consumer plastics: Think of discarded bottles (HDPE, PET), containers, films (LDPE, LLDPE), and various mixed plastic streams from households and businesses.

Industrial plastic scrap: Waste generated during manufacturing processes, such as off-cuts, rejected parts, and production line leftovers from various plastic types.

Agricultural plastics: Used films, greenhouse covers, and irrigation pipes made from materials like LDPE and PVC.

Packaging waste: A significant contributor to the waste stream, including discarded trays, tubs, and protective packaging materials.

Our compression molding technology provides a tangible solution for industries grappling with substantial plastic waste generation:

Manufacturing: Facilities producing plastic goods often generate significant amounts of scrap. Our machines enable them to recycle this in-house or through specialized recyclers, turning waste into durable pallets for their own logistical needs.

Agriculture: The agricultural sector utilizes a vast quantity of plastic films and pipes. Our machines can process this collected waste into sturdy pallets for transporting produce and supplies.

Retail and Logistics: The movement of goods relies heavily on pallets. By utilizing pallets made from recycled waste plastics, these industries can significantly reduce their environmental footprint and contribute to a circular economy.

Waste Management and Recycling: Our machines are an invaluable asset for recycling facilities, allowing them to process mixed and challenging plastic waste streams into high-value products, diverting them from landfills.

Environmental Responsibility: Significantly reduces the amount of plastic waste sent to landfills, conserves natural resources, and lowers carbon emissions associated with producing new plastic.

Cost-Effectiveness: Utilizing recycled materials lowers raw material costs, making the final pallets an economically viable alternative to virgin plastic or wooden pallets.

Durability and Longevity: Compression molding creates robust and long-lasting pallets resistant to moisture, rot, pests, and splintering, offering a superior return on investment.

Consistency and Safety: Our machines produce pallets with consistent dimensions and weight, ensuring smooth operation in automated systems and reducing workplace hazards associated with damaged wooden pallets.

At PalletMach, we are proud to contribute to a more sustainable future by providing cutting-edge compression molding pallet machines. We believe in the power of recycling and the potential of waste plastic to be transformed into valuable resources.

Contact us today to learn more about how our technology can help your industry turn its waste challenges into sustainable solutions.