In the modern logistics and packaging industry, pallets are essential tools for transportation and storage, with massive usage across the globe. However, traditional wooden pallets come with high costs, heavy reliance on timber, and strict fumigation requirements. As environmental policies tighten and companies pursue sustainable growth, pressed pallets have emerged as a promising alternative—and the pressed pallet machine is the key equipment enabling this green transformation.

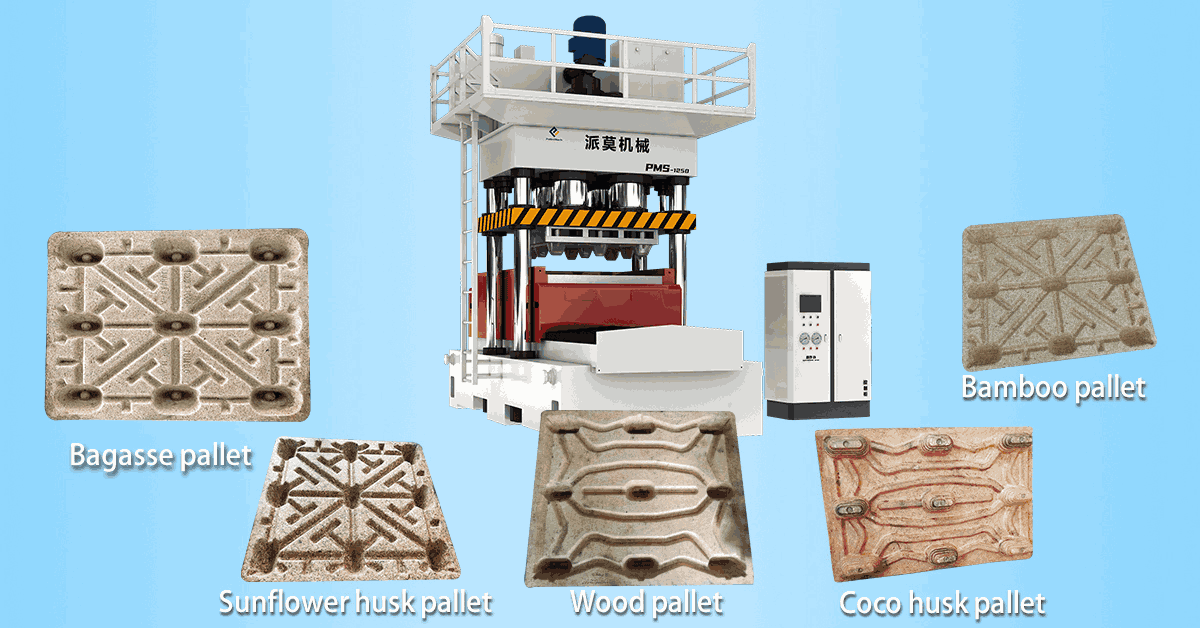

A pressed pallet machine is a specialized device that transforms discarded wood chips, sawdust, rice husks, straw, waste paper, bamboo powder, and even certain plastics into solid, molded pallets using high-temperature and high-pressure molding technology. Its core lies in precision mold design and thermal pressing systems, converting low-value waste into durable, high-performance pallets.

Unlike traditional wooden pallets that require large quantities of solid wood, pressed pallets are made from widely available and often low-cost or even free waste materials—from furniture factory offcuts and paper mill pulp residue to agricultural leftovers. With minimal preprocessing, these materials can be molded into pallets, significantly cutting down production costs. Studies show that the unit cost of a pressed pallet can be 20% to 50% lower than that of conventional wooden pallets with similar load capacity.

Pressed pallets not only use renewable resources but are also biodegradable and recyclable, aligning with global environmental standards such as ISPM 15. This means no fumigation is required for international shipments, reducing chemical use and regulatory burden. The closed-loop system of “waste → product → recycling” supports circular economy models and enhances a company’s environmental image.

Modern pressed pallet machines feature a high degree of automation—from feeding and heating to pressing, cooling, and demolding. Equipped with precision-controlled molds and temperature systems, they enable continuous, high-efficiency production. The resulting pallets are clean, standardized in size, nail-free, and splinter-free—ideal for automated warehouses and export logistics.

The pressed pallet machine is more than just equipment—it is a solution that embodies the principles of recycling and environmental responsibility. In the era of carbon neutrality and green trade, pressed pallets offer a sustainable path forward for the packaging and logistics industry. Choosing a pressed pallet machine means investing in a cleaner, more efficient, and eco-friendly future.