Presswood pallet molding technology, using agricultural and forestry waste as raw material to create low-cost, high-strength, zero-waste recycled pallets.

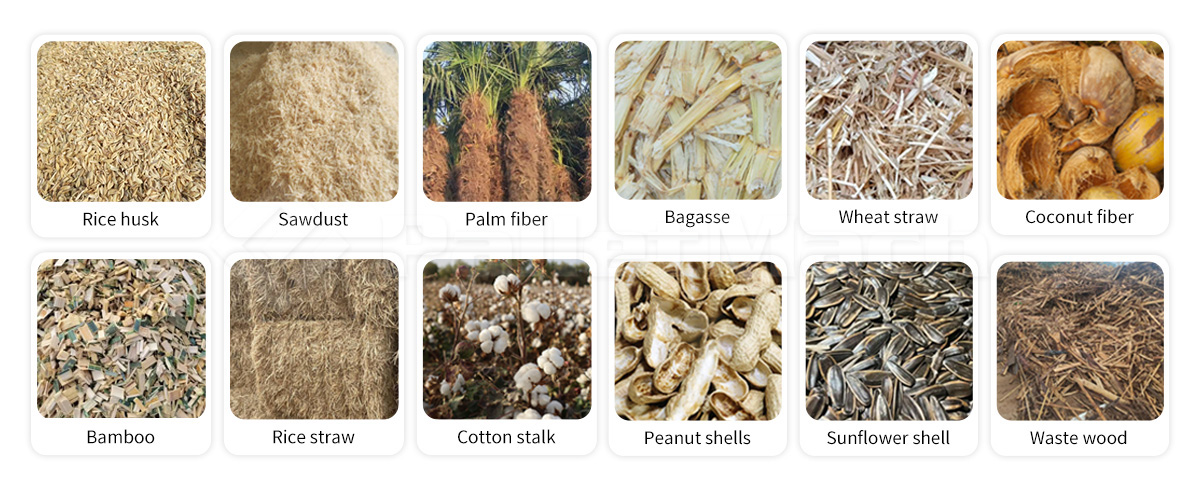

Presswood pallet machines utilize waste wood and agricultural residues (such as straw, coconut husks, and peanut shells), converting them into durable pallets. This not only reduces environmental impact but also minimizes the reliance on natural timber resources.

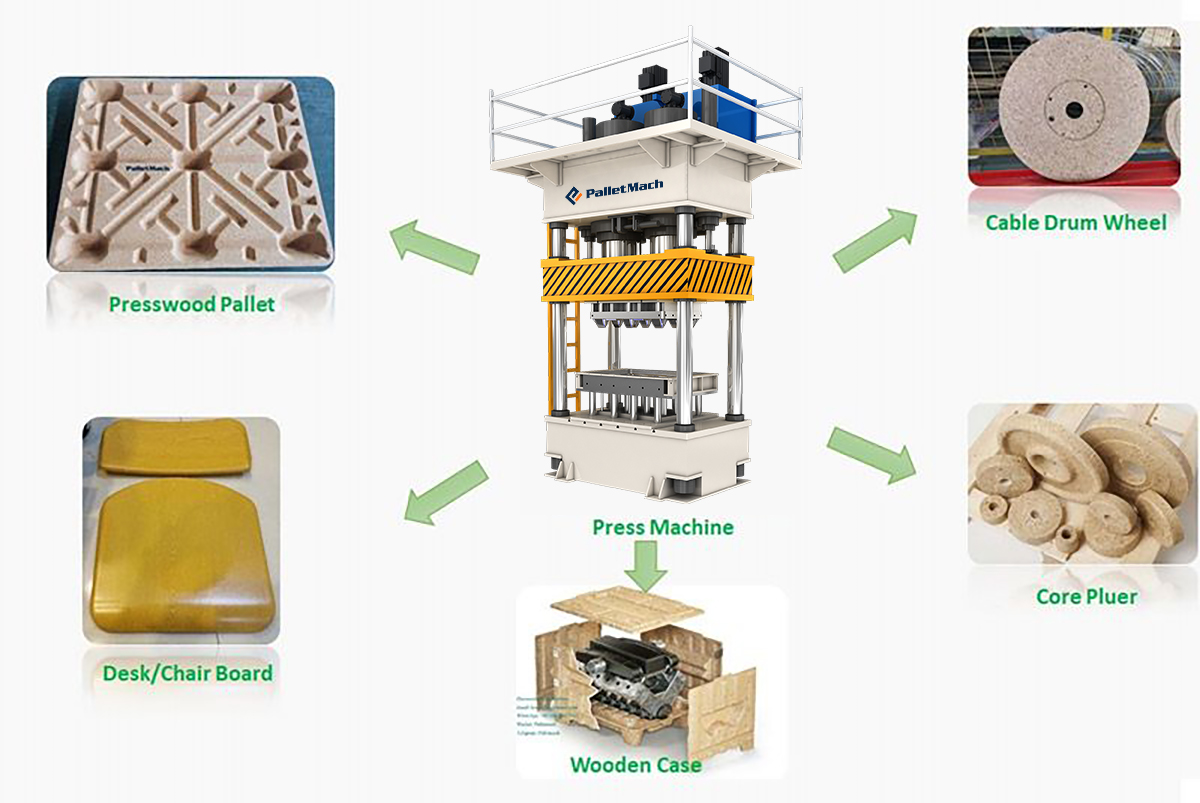

The final product: Pressed Wood Pallet; Presswood Core Plug; Presswood Cable Reel , Wooden Case etc.

The production process includes:

①Crushing->②Drying->③Glue Mixing->④Pressing->⑤Edge Sanding->⑥Finished Product

This whole process can be fully automatic or semi-automatic, customized according to your requirements.

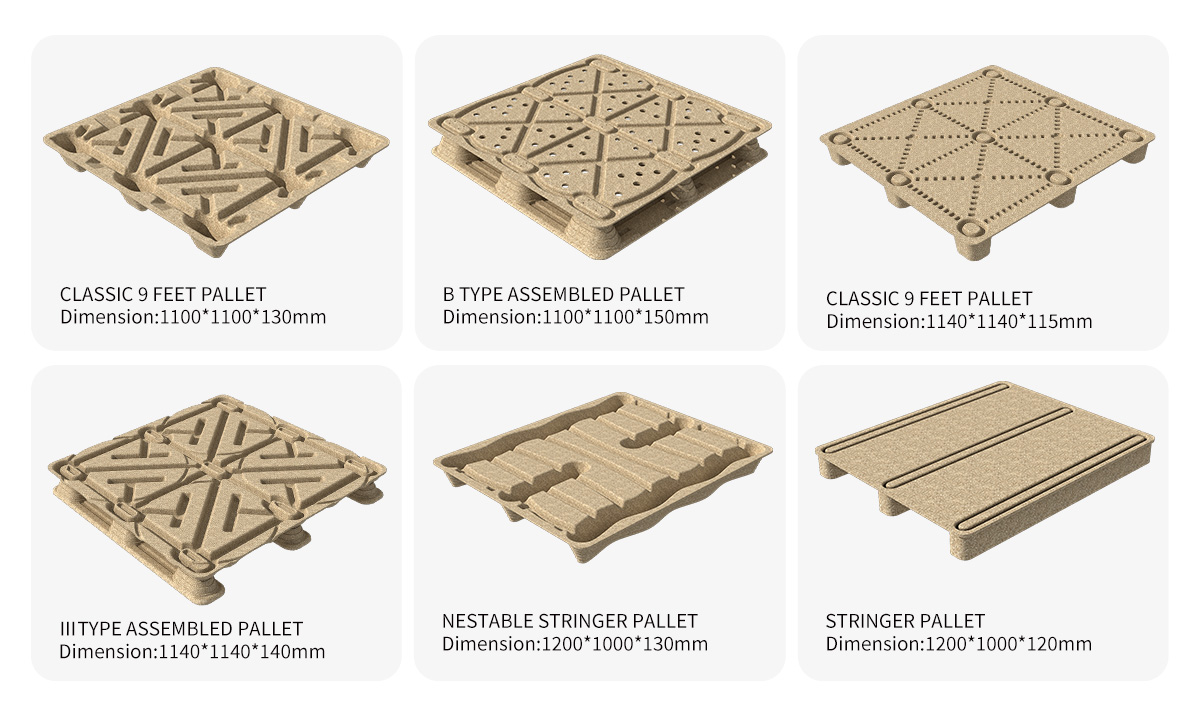

Presswood pallets are ideal for logistics and transport, warehouse storage, export packaging, agricultural goods, home appliances, construction materials, and more. They are an excellent alternative to traditional wooden or plastic pallets.

6.Technology parameters of presswood pallet machine

|

Model |

PM-630 |

PM-800 |

PM-1000 |

PM-1250 |

PM-1600 |

PM-2000 |

|

Dimension(m) |

2.9×2.05×5.1 |

3×2.05×5.2 |

3.1×2.05×5.35 |

3.2×2.05×5.5 |

3.3×2.05×5.6 |

3.4×2.05×5.7 |

|

Weight(t) |

16 |

18 |

20 |

25 |

30 |

42 |

|

Power(kw) |

30 |

30 |

37 |

37 |

45 |

55 |

|

Capacity(pcs/set/h) |

7-13 |

7-13 |

7-13 |

7-13 |

7-13 |

7-13 |

|

Pressure(t) |

0-630 |

0-800 |

0-1000 |

0-1250 |

0-1600 |

0-2000 |

|

Hydraulic cylinder diameter(mm) |

400 |

450 |

500 |

550 |

600 |

650 |

|

Hydraulic cylinder quantity |

4 pieces |

|||||

|

Voltage |

Customized |

|||||