In today’s fast-paced global economy, every business seeks an edge – a way to cut costs, boost efficiency, and champion sustainability. Pallets, the unsung heroes of logistics, have often been inefficient, costly, and environmentally burdensome. But what if you could transform waste into a valuable asset, streamline your supply chain, and significantly reduce your ecological footprint, all with one innovative solution?

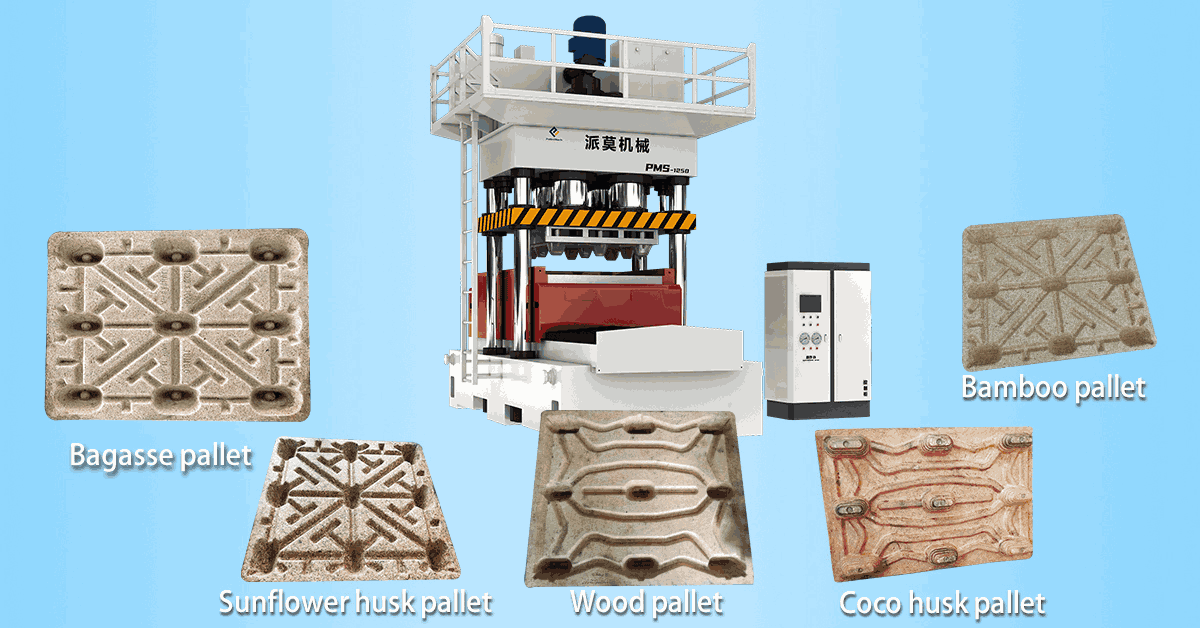

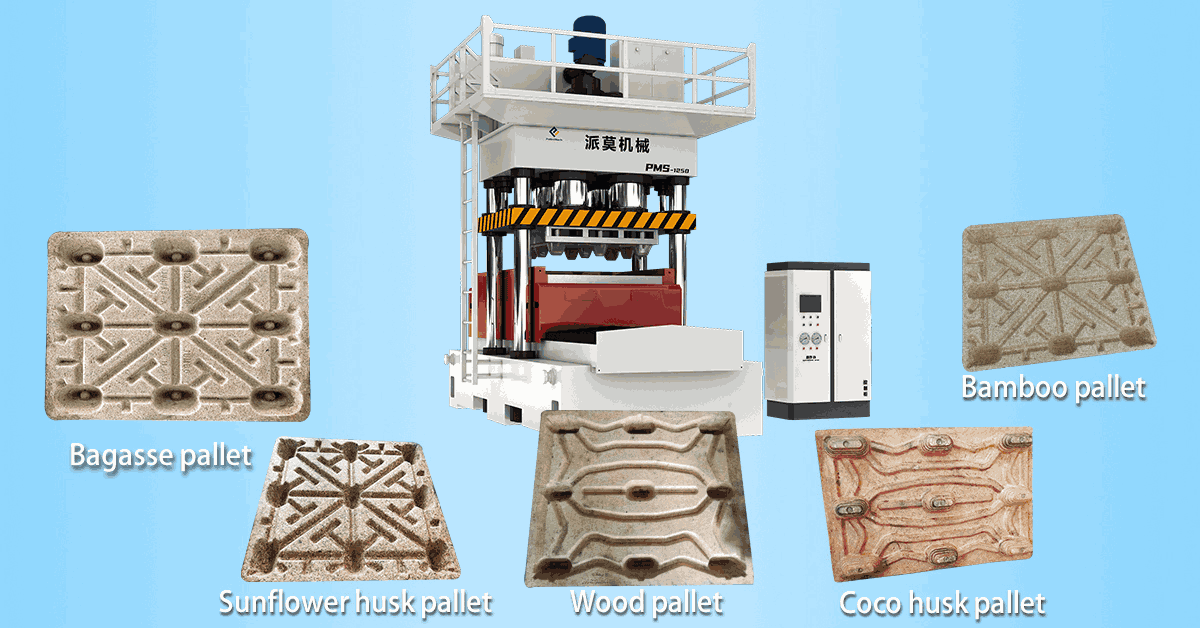

Enter the Molded Wood Pallet Machine – a groundbreaking technology that’s revolutionizing how goods are moved, stored, and shipped worldwide.

From Waste to Wealth: The Power of Transformation

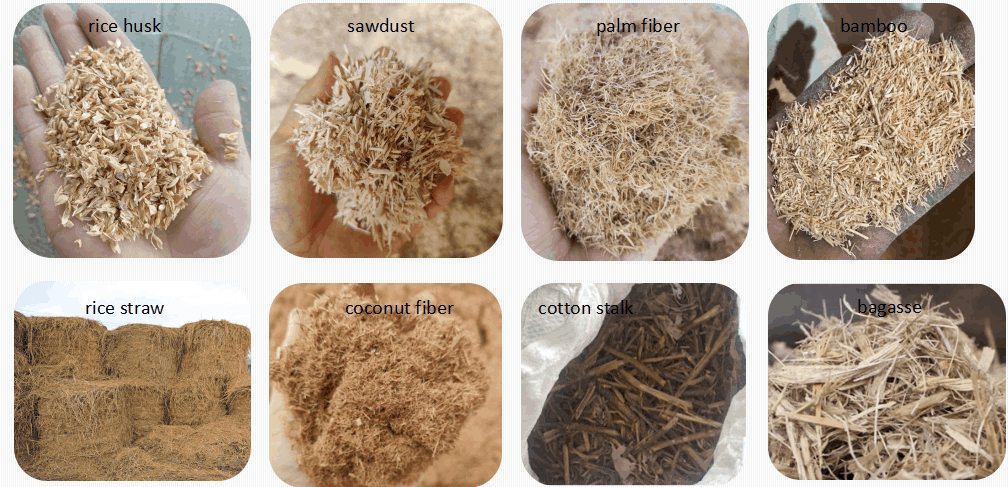

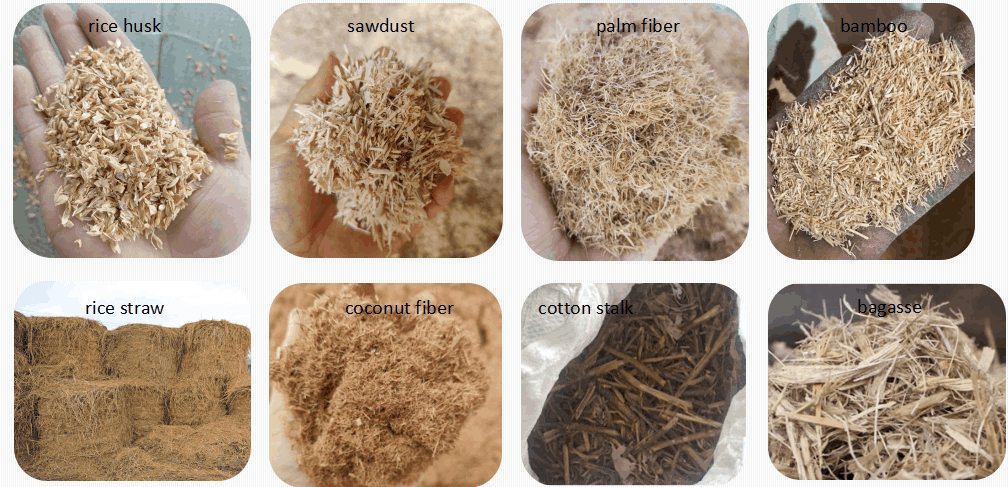

Imagine turning your wood by-products, sawdust, wood chips, or even agricultural residues like straw and rice husks, into high-performance, export-ready pallets. This isn’t a futuristic dream; it’s the core capability of the molded wood pallet machine.

At its heart, this machine employs a sophisticated hot pressing process. Raw wood fibers, mixed with a specialized binder, are subjected to immense pressure (up to 1300 tons) and high temperatures (up to 230°C) within precision-engineered molds. This transformative process densifies the material, creating a single, homogenous pallet that is robust, consistent, and ready for the rigors of global trade.

The mold wood Pallet machines feature robust three-beam, four-column structures, ensuring high strength, rigidity, and precision, which directly translates to the quality and consistency of the final pallets .

Unlocking Unprecedented Advantages: Why Molded Wood Pallets Are Your Next Strategic Investment

The benefits of integrating a molded wood pallet machine into your operations are multifaceted, impacting your bottom line, environmental standing, and operational flow.

1. Economic Empowerment: Drive Down Costs, Boost Profits

- Material Cost Revolution:Convert wood waste and agricultural residues into valuable pallets, drastically reducing material costs. Some reports indicate material costs as low as $0.12/kg compared to $1.05/kg for traditional materials.

- Freight Savings:Molded wood pallets are 35-60% lighter than conventional hardwood pallets, leading to lower transportation expenses, especially for air freight. Their nestable design allows a standard 40-foot container to hold approximately 1650 compressed pallets, optimizing shipping volume.

- Space Optimization:Their unique nestable and stackable design saves up to 66-70% in storage and transportation space, freeing up valuable warehouse real estate.

- ISPM-15 Exemption:The high-temperature manufacturing process classifies molded pallets as “processed wood,” exempting them from costly and time-consuming ISPM-15 fumigation or heat treatment for international trade.

2. Environmental Stewardship: A Greener Supply Chain

- Waste Utilization:Repurpose wood by-products and agricultural waste, diverting significant volumes from landfills and minimizing methane emissions.

- 100% Recyclable:At the end of their lifespan, molded wood pallets can be shredded and re-glued to produce new pallets, fostering a true circular economy.

- Lower Carbon Footprint:Reduced reliance on new timber, minimized waste, and optimized transportation contribute to a significantly lower overall carbon footprint. Some businesses even earn carbon credits.

3. Operational Excellence: Enhance Performance and Safety

- Durability and Load Capacity:Designed for robust performance, these pallets can withstand substantial loads (e.g., dynamic load capacity of 2 tons, static load capacity exceeding 6 tons). Their stiffness often surpasses many nestable plastic pallets, reducing product damage.

- Pest and Mold Resistance:The high-heat manufacturing process effectively eliminates insects and prevents mold and fungus growth, making them ideal for hygiene-sensitive industries.

- Cargo Protection & Safety:The one-piece design, free of nails, screws, or splinters, significantly reduces the risk of product damage and minimizes employee injuries.

- Consistent Quality:The molding process ensures a consistent size and shape for every pallet, highly beneficial for automated warehousing and palletizing systems.

Industries Embracing the Future

Molded wood pallets are rapidly gaining traction across diverse sectors, including manufacturing, logistics, transportation, food, pharmaceutical, chemical, electronics, building materials, and e-commerce, due to their unique properties and benefits.

Impressive ROI: Investing in Your Future

The economic return on investment of the molded wood pallet machine is impressive. The payback period is as short as 11 to 18 months and the profit margin is very attractive.

Ready to Transform Your Supply Chain?

The global market for molded wood pallets is experiencing robust growth, driven by increasing e-commerce, global trade requirements, and a heightened focus on corporate sustainability. By investing in a molded wood pallet machine, you’re not just acquiring equipment; you’re adopting a strategic solution that aligns with the future of logistics.

Contact us today to learn how this innovative technology can revolutionize your operations, reduce costs, and elevate your commitment to a sustainable future