In an era defined by environmental responsibility, businesses are under increasing pressure to minimize waste and embrace sustainable practices. Traditional industrial operations often generate significant volumes of wood waste and agricultural residues, which typically end up in landfills, posing environmental challenges and incurring disposal costs.

Molded Wood Pallet Machine: This innovative technology not only addresses the problem of waste but transforms it into a valuable, high-performance product, fostering a true circular economy.

Industries like sawmills, furniture manufacturing, and agriculture produce vast quantities of by-products such as sawdust, wood chips, shavings, and various plant stalks. Historically, managing this waste has been a costly and environmentally detrimental process, contributing to landfill burdens and methane emissions from decomposing organic matter.

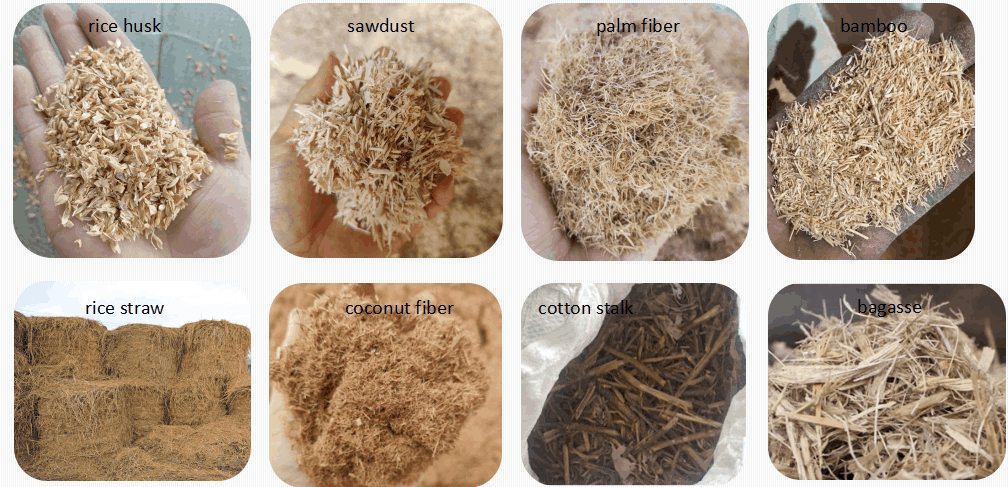

The molded wood pallet machine stands at the forefront of sustainable manufacturing by utilizing an incredibly broad spectrum of raw materials:

This extensive range of acceptable raw materials means that businesses can convert what was once a disposal cost into a valuable input for pallet production. For example, one lumber mill transformed its annual waste disposal costs of $78,000 into a $214,000 profit by producing sellable pallets from its sawdust.

The environmental benefits extend far beyond waste utilization:

For businesses struggling with the efficient and environmentally sound disposal of wood and agricultural waste, the molded pallet machine offers a comprehensive solution. It provides an in-house capability to transform problematic waste streams into a high-demand product, eliminating disposal costs and generating new revenue streams. This not only solves a critical operational challenge but also positions your company as a leader in sustainable practices.

By investing in a molded wood pallet machine, you’re not just acquiring equipment; you’re adopting a strategic solution that transforms your waste into a valuable asset, enhances your environmental stewardship, and contributes to a more sustainable future for your business and the planet.